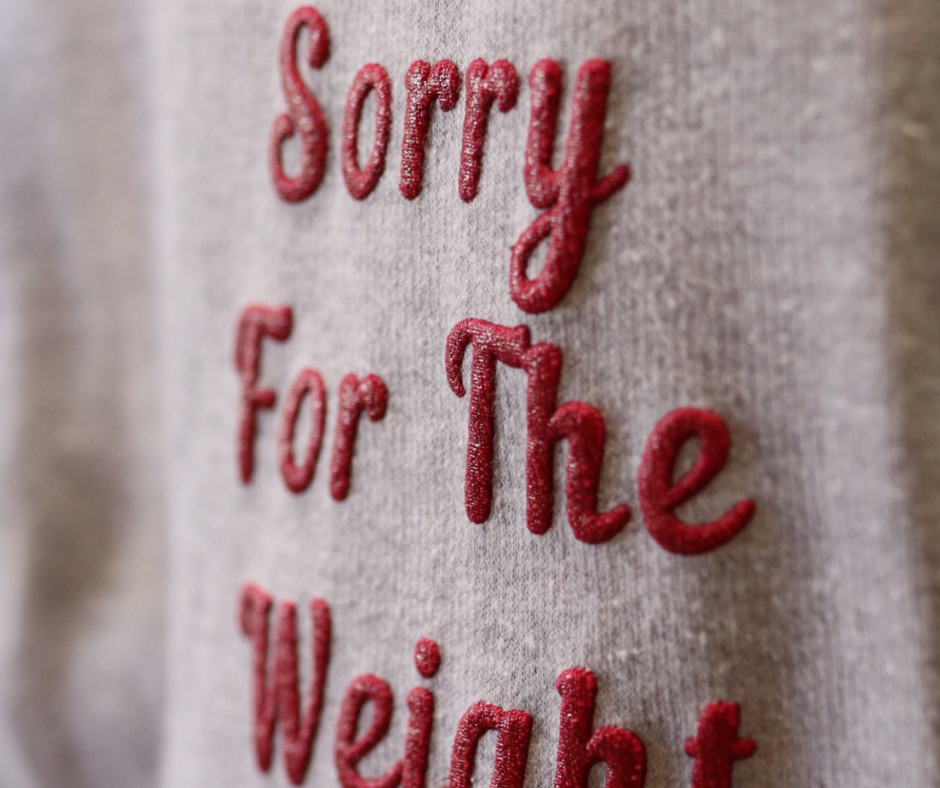

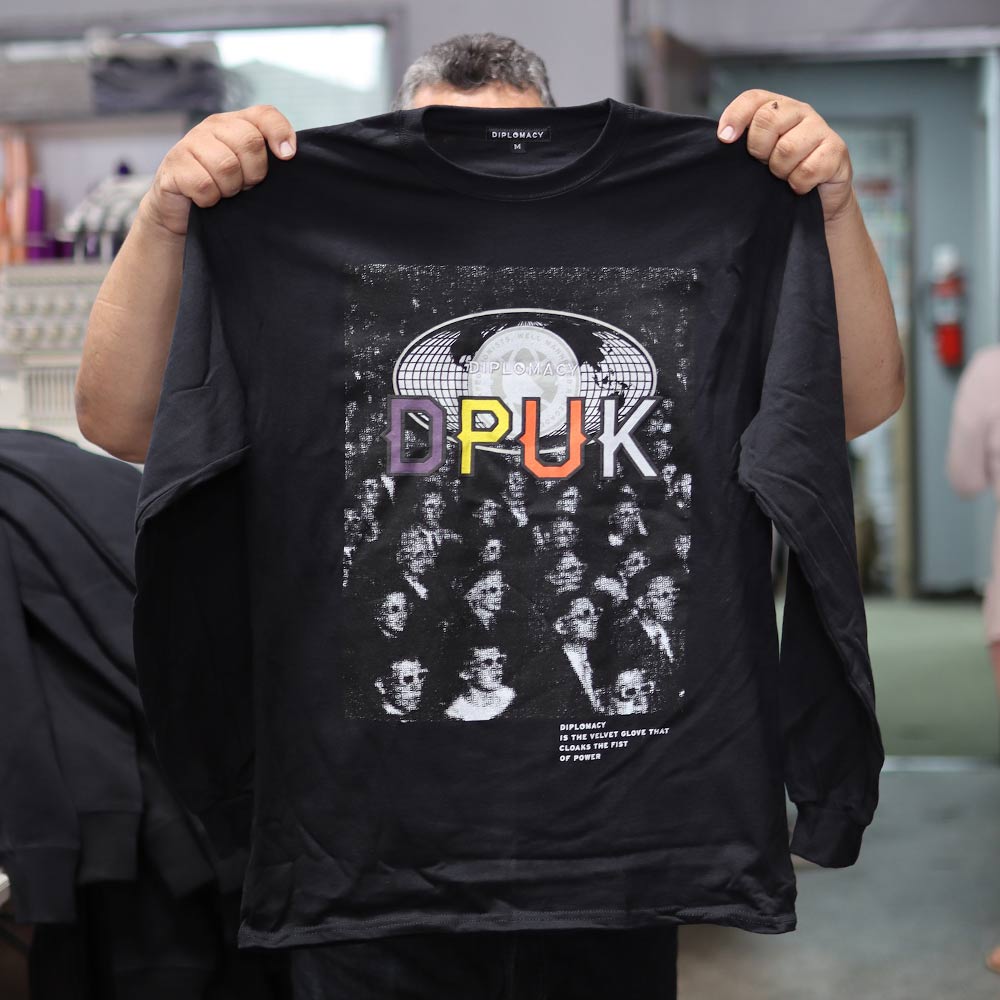

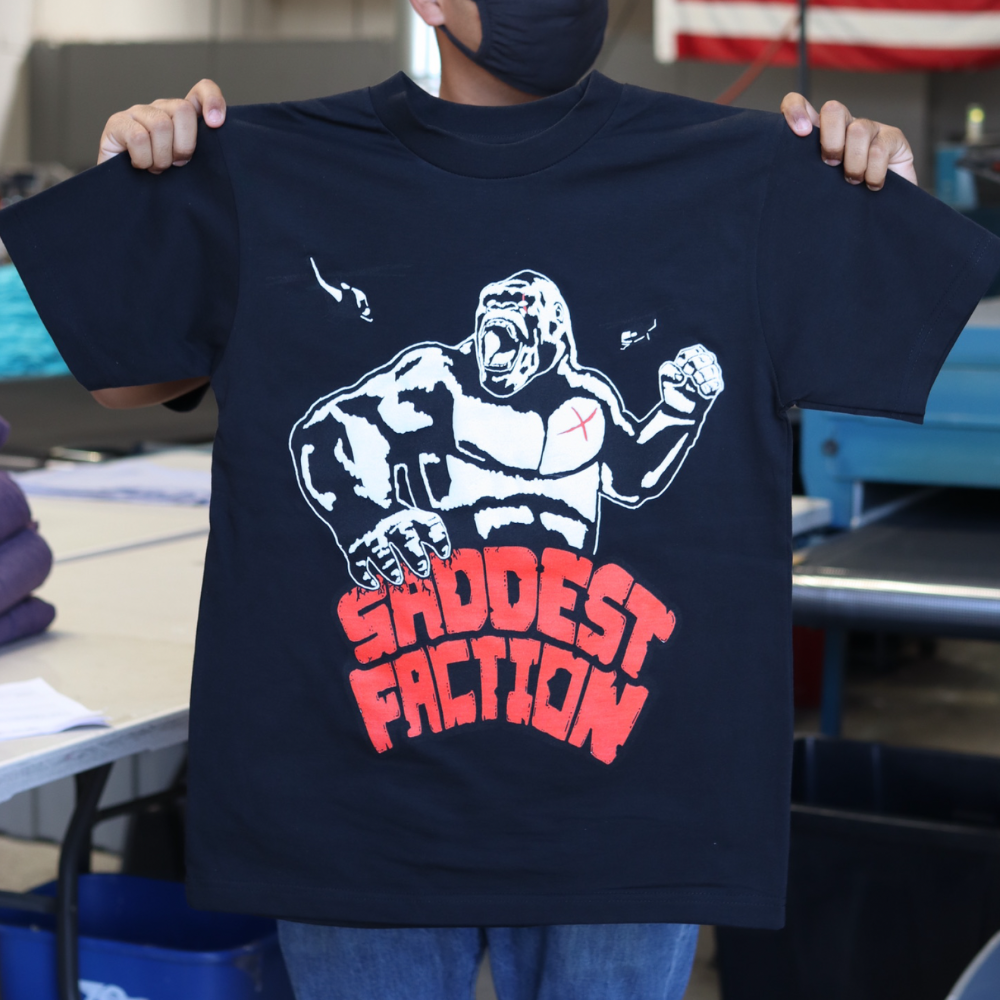

3D Effect

What is Puff Ink & How Does It Work?

Puff ink isn't your typical ink; rather, it's an additive blended with plastisol ink prior to the printing process. Once heated to approximately 320 degrees Fahrenheit, the initially flat print undergoes a fascinating transformation, puffing up to create a 3D embossed texture that elevates from the fabric's surface. This technique gives a distinctive raised finish.

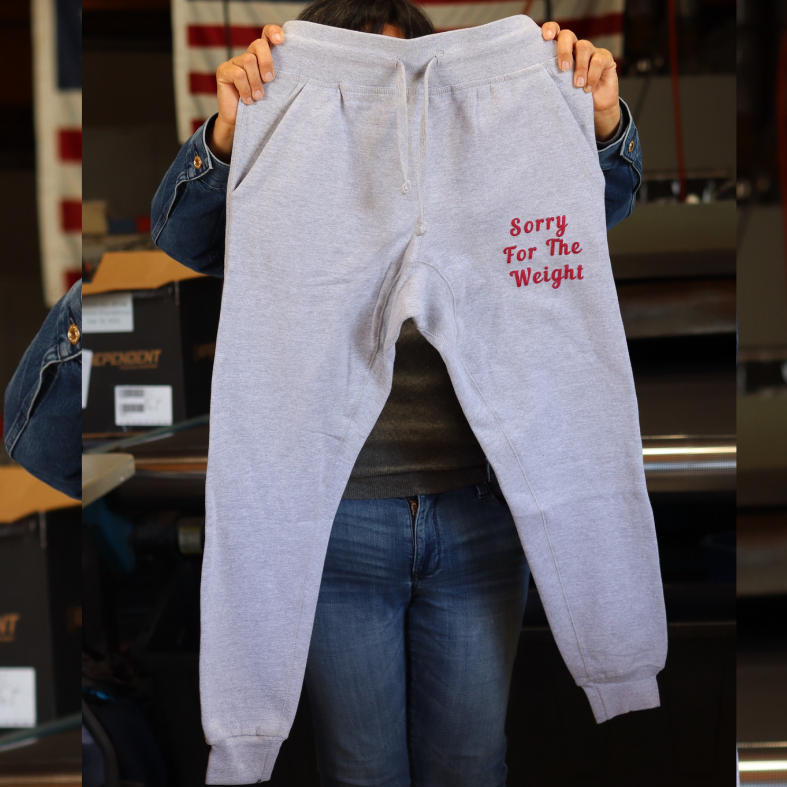

Puff can be incorporated into select portions of the design, particular colors, or across the entire printed area. If you have precise instructions or preferences concerning a puff print, we encourage you to reach out to one of our account representatives to guide you through the process.

- Ability to do text and outlines

- Able to apply puff printing across the entire design or on specific parts.

- Avoid fine details

- Better perceived retail value

Request a Call Back

An account rep requires a minimum order of 50 pieces to process your order.