Selecting the Right Foundations for Your Screen Printing Project

When it comes to screen printing, the materials and inks you choose can make or break your project. This post will guide you through selecting the best materials and inks to ensure your screen printing endeavors are successful and high-quality.

Understanding the Importance of Material Choice

Fabric Types: The Canvas for Your Art

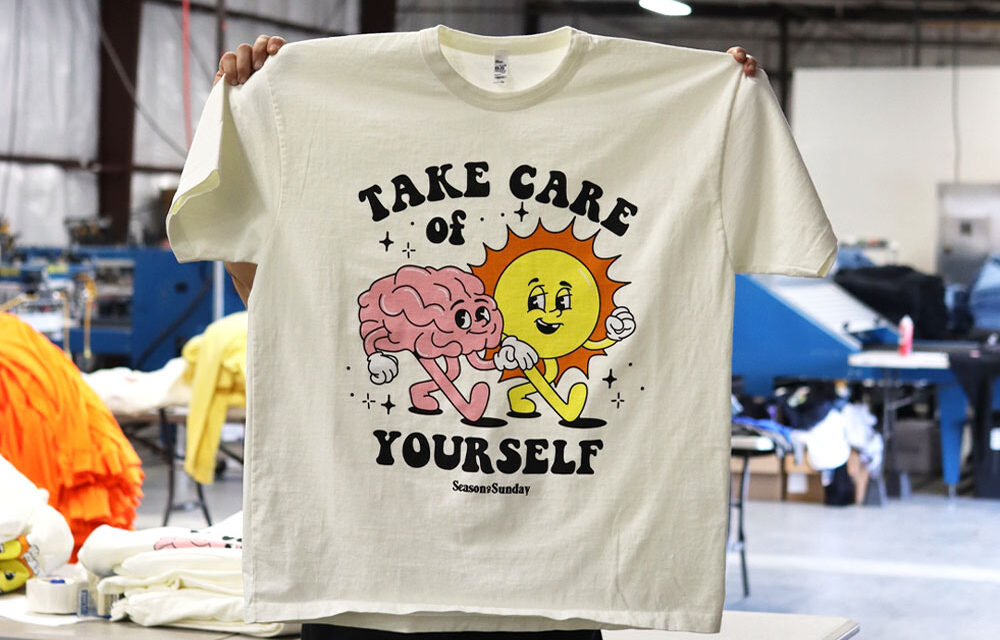

- Cotton: Ideal for screen printing due to its smoothness and absorbency. Offers a classic, vintage look.

- Polyester and Blends: Trickier to print on due to lower absorbency and potential dye migration. Requires specialized inks and techniques.

- Specialty Fabrics: Materials like nylon, silk, and canvas each have unique properties and may need specific inks or pretreatment for optimal results.

Consider Fabric Color

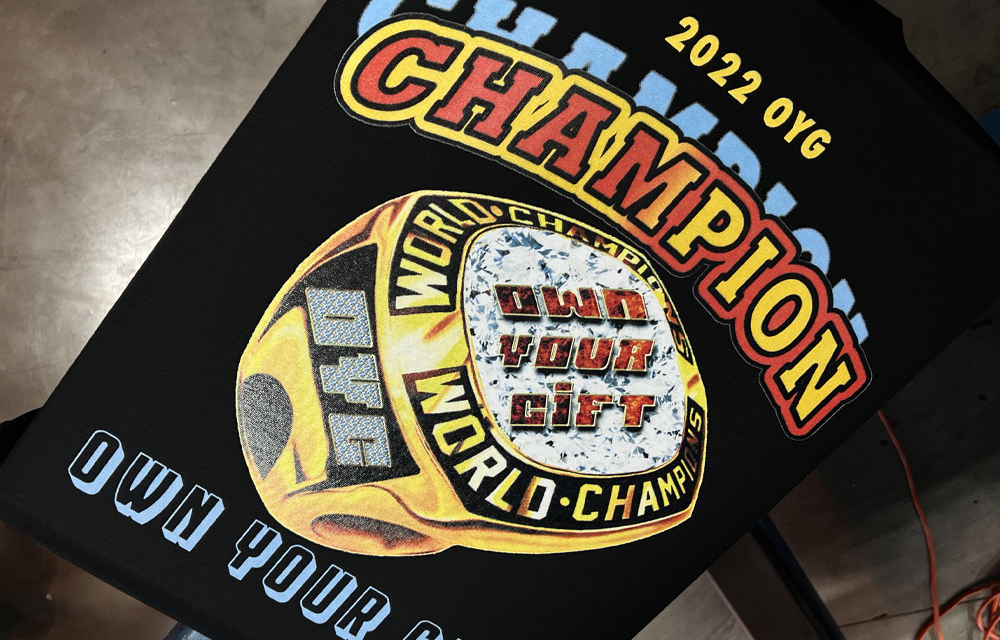

- Light vs. Dark Fabrics: Dark fabrics often require a base layer of white ink for colors to show up vividly. Light fabrics are more forgiving and versatile in terms of ink colors.

Choosing the Right Inks

Plastisol Inks: The Popular Choice

- Versatile and User-Friendly: Plastisol inks are the most commonly used in screen printing. They are easy to work with and provide vibrant, opaque colors.

- Curing Considerations: Require proper curing (heating) to ensure durability.

Water-Based Inks: For a Softer Touch

- Soft Hand Feel: Water-based inks soak into the fabric, resulting in a print that’s soft to the touch.

- Eco-Friendly Option: Generally more environmentally friendly than plastisol, but have a longer drying time and can be more challenging to work with.

Specialty Inks and Additives

- Metallics, Glitters, and Reflectives: Add a unique touch to your prints but require testing and practice to perfect.

- Puff Additives: Create a raised, textured effect on prints.

Screen Mesh Count: Matching Your Material and Ink

Understanding Mesh Counts

- Higher Mesh Counts: Finer details and thinner inks. Best for water-based and detailed designs.

- Lower Mesh Counts: Thicker inks like plastisol. Suitable for bold, less detailed images.

Pre-Treatment and Post-Treatment Processes

Preparing Your Material

- Pre-Treatment: Some fabrics, especially dark colors, may require a pre-treatment to ensure ink adhesion and vibrancy.

Curing and Setting the Ink

- Proper Curing: Essential for durability. Plastisol inks, for example, require a heat cure to set properly.

Environmental Considerations and Compliance

Choosing Eco-Friendly Options

- Eco-Inks: Look for inks that are free from harmful chemicals and heavy metals.

- Compliance: Ensure your materials and inks comply with industry standards and regulations, particularly if you’re producing commercial or children’s wear.

In summary, choosing the right materials and inks is a critical step in the screen printing process. It requires a balance between the type of fabric, the ink’s properties, and the desired outcome of your project. By considering these factors, you can produce high-quality, durable screen prints that stand out. Next up in our series, we’ll explore the step-by-step process of screen printing, guiding you through each stage to achieve the best results.